RWIC doesn’t usually advertise on billboards. Instead, this season our branding was printed on a horse — an unconventional and eye-catching form of advertising at local equestrian competitions. It might sound playful, but it reflects something deeper: how creative advertising, community engagement, and collaboration can all intersect to create shared value.

Community Engagement

Equestrian events rely on more than just riders and horses. They bring together organizers, families, trainers, and local businesses. Sponsorship helps make these events possible, ensuring individual rider-and-horse teams can participate. In turn, those teams strengthen the event itself, drawing in more competitors and more community involvement.

Creative Advertising

A logo on a horse isn’t traditional marketing, but it works. Hundreds of region specific attendees see it — from professionals and business owners to community leaders. It sparks conversations and connects RWIC core values like support, perseverance, and partnership.

Mutual Benefit

The real strength lies in how everyone benefits:

- The advertiser gains visibility.

- Rider-and-horse teams receive support to reach competition goals.

- The event thrives because more participants can attend.

- Even transportation becomes more efficient: a full trailer is more cost-effective than a partial one — just as in logistics, where LTL and FTL freight are most cost effective when resources are optimized.

It’s a cycle of support, where each contribution strengthens the next.

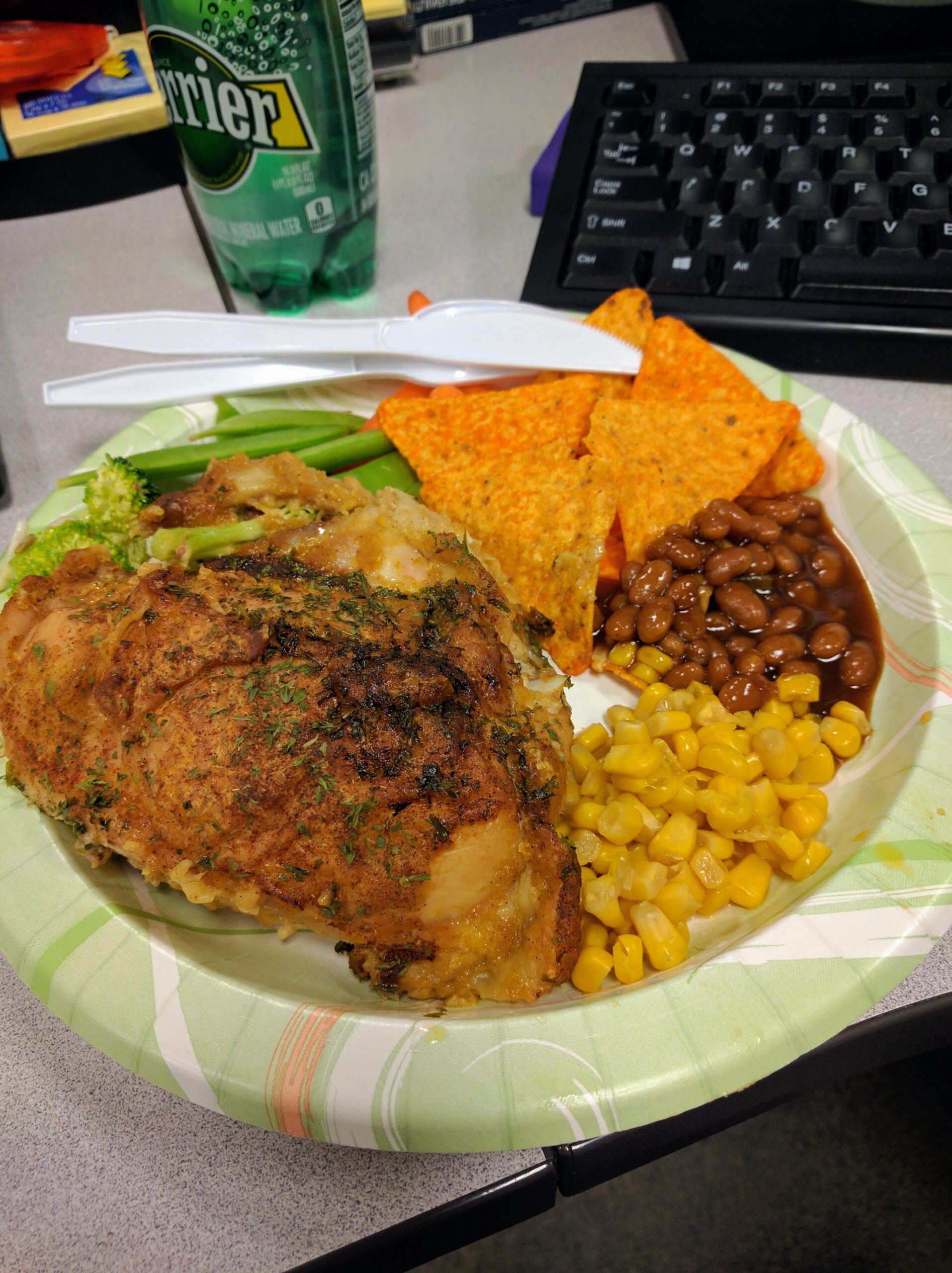

A Parallel in Client Work

This principle plays out in RWIC’s consulting projects too. Recently, a client recognized our role in a high-stakes project with a small thank-you gift. A thoughtful gesture, but what stood out most was the reminder that success comes from teamwork. Multiple RWIC team members provided operational support and business/technology alignment, while the client brought situational expertise and their staff executed with commitment. Like the horse show, each role mattered, and the outcome depended on collaboration.

Creative advertising, community sponsorship, and collaborative consulting may seem like different worlds, but the underlying lesson is the same: when effort aligns with opportunity, everyone benefits. Whether it’s in the show ring or in a cross-border warehouse, RWIC is proud to champion that approach — building systems of support where success carries farther than any one of us could take it alone.